What are the features of pet recycling line?

The main purpose of the plastic washing line is to clean and recycle plastics. Plastic washing lines are mainly divided into three categories according to the materials, one is soft plastic washing line equipment, the other is hard plastic washing line equipment,and pet recycling washing line.

Soft materials include agricultural film, film, shade net, fishing net, PP woven bag, plastic bag, cement bag, etc., and hard materials usually include plastic shell of household appliances, plastic bottles, plastic buckets, plastic helmets, computer shell, TV plastic shell, plastic table and stool, plastic pipe, etc. These soft and hard waste plastics can be recycled and reused, which not only saves resources but also protects the environment and increases economic value, which is of great significance.

What is the production process of the Pet Bottle Washing Plant?

Plastic bottles and plastic films have different processing procedures. Plastic bottle processing is usually called plastic bottle washing line, plastic crushing and washing line, HDPE/PET bottle crushing and washing line, etc.; film processing includes PE film washing line, PP woven bag washing line, etc.

PE/PP film recycling and washing line process: After crushing, friction washing, water washing, dehydration, hot air drying, high-temperature melting, cooling and other processes, waste and dirt become clean flakes for use in granulators.

HDPE bottle recycling and washing line process: Crushing(Waste plastics are crushed into small pieces in the waste plastic crusher)Cutting and washing: (The crushed plastic enters the cleaning equipment and is thoroughly cleaned. This process can remove dirt, grease and other impurities in the plastic to ensure the purity of the recycled particles.) Dehydration: (The washed plastic fragments are dehydrated by the dehydrator to remove excess water in preparation for the subsequent granulation step.) Granulation: (The dehydrated plastic fragments are fed into the plastic granulator, which is melted and extruded using a granulator to form continuous plastic strips.)

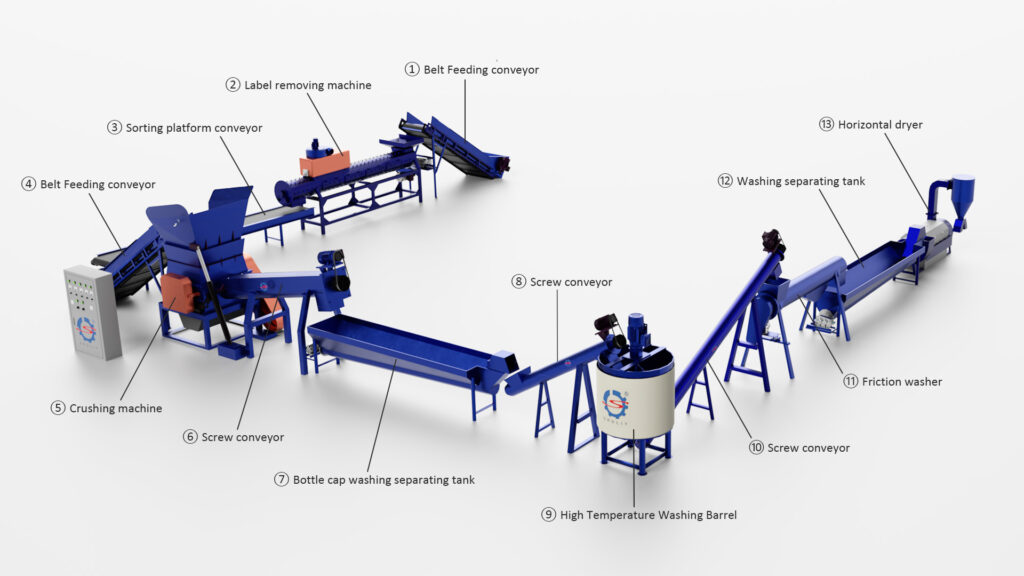

PET bottle recycling and washing line process: climbing conveyor → label removal machine → sorting conveyor → climbing conveyor → PET bottle crusher → screw conveyor → separator → screw conveyor → high temperature cleaning barrel → screw conveyor → kneading cleaning machine → PET, PP, PP cleaning and separation machine → PET fragment dehydration machine → final product.

What are the features of pet recycling line?

- The PET recycling production line has a high degree of automation, saving labor costs and easy maintenance.The PET bottle recycling production line is highly automated and only requires 3-4 operators for the entire production process. The output includes 200-1000kg/h. We can also design recycling production lines with larger output according to user requirements.

- Waste bottles or flakes are broken, cleaned and dried to become bottle flakes.The final product of the plastic bottle recycling production line can meet the requirements of first-class clean bottle flakes.

- The final products are clean, transparent sheets or film fragments; they can be used for downstream production.

- Moisture content <1%, impurities 300PPM.

- Parts in contact with water or raw materials are made of SUS304 or 306 stainless steel with a thickness greater than 3mm to ensure a long service life.

- The top three plastic recycling manufacturers in China.

- The complete plastic PET recycling machine complies with CE safety certification and ISO9001 certificate.

- It can be equipped with a corresponding granulation system according to production requirements.

- The equipment of the PET bottle recycling production line can be flexibly matched. According to the customer’s raw materials, different washing machines and dryers can be selected. Please contact us for details.