Plastic Film Pelletizing Machine

Plastic Film Pelletizing Machine Introduction:

The PP PE plastic film granulator integrates the functions of crushing, compaction, melting and extrusion, and is designed to convert waste PP PE and other plastics into recycled plastic particles. In addition to granulating waste plastic films, this granulator can also granulate PP PE woven bags, cement bags, pp raffia, plastic packaging bags, etc. The final product of the plastic granulator is recycled granules or pellets, which can be directly used in pipe extrusion, plastic manufacturing, film blowing and plastic injection. Shuliy Group has been manufacturing plastic film granulators for more than 20 years, helping many recycling plants start their own businesses and make huge profits.

raw materials and final product of plastic pelletizer

Plastic film pelletizing machine is widely used in the processing of all kinds of plastic film wastes such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and so on. These wastes can include plastic packaging films, plastic bags, agricultural films, etc. Through the processing of the plastic granulator, they can be converted into high-quality recycled plastic pellets for production and reuse.

final product

Plastic Film Pelletizing Technical specifications

Shuliy has a wide range of plastic film recycling machines to help customers improve their plastic recycling efficiency, if you need other models of plastic pelletizing recycling machines,Shuliy Group offers more pelletizer machine models with larger power and output based on your request,please feel free to contact us.

| Model | SL-125 | SL-150 | SL-180 | SL-200 | SL-220 |

| Screw diameter | 125mm | 150mm | 180mm | 200mm | 220mm |

| Spindle speed | 50-70/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min |

| Main motor power | 30kw | 37kw | 55kw | 75kw | 90kw |

| Weight | 1.8T | 2T | 2.2T | 2.8T | 3.2T |

| Dementions | 2.6*0.7*0.7 | 3.0*0.7*0.8 | 3.2*0.7*0.8 | 3.5*1*1 | 3.8*1.2*1 |

| Capacity | 180KG/H | 300KG/H | 350KG/H | 380KG/H | 420KG/H |

Plastic pelletizing machine working principle

The working principle of plastic film pelletizer is based on melt extrusion technology. The key steps include raw material pre-treatment, plasticizing and melting, extrusion pelletizing, and pellet cooling.

More detailed information

Plastic extruder system:

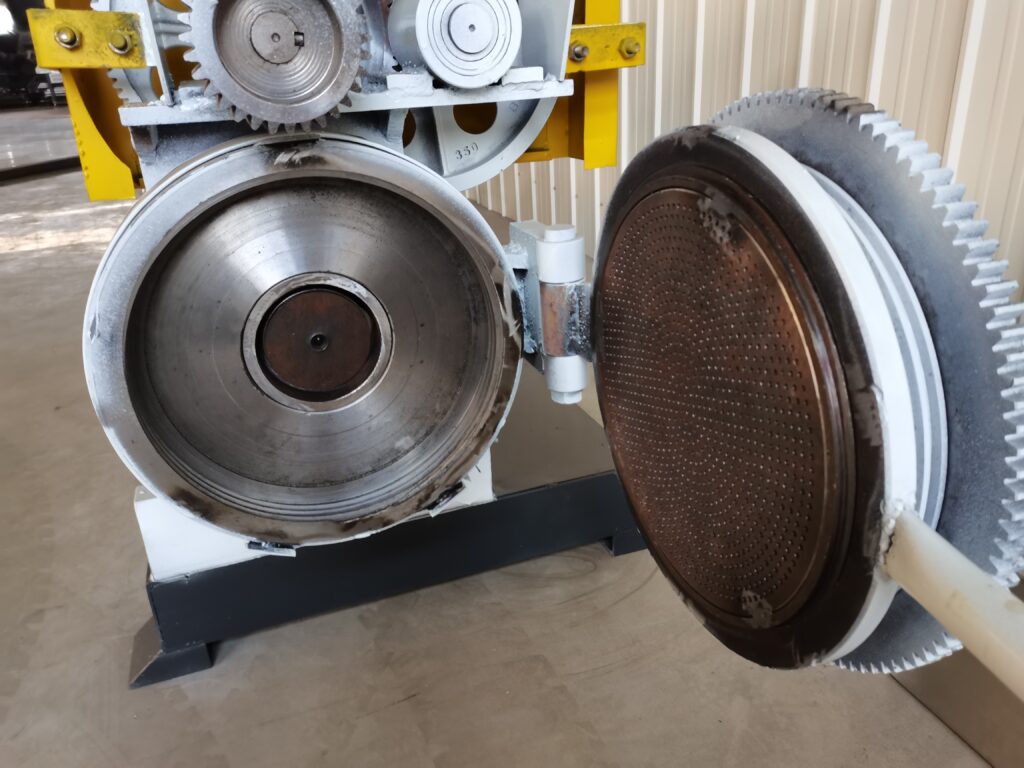

The main machine of the plastic granulator is the extruder system, which is composed of a transmission system, a heating system, an extrusion system, a cooling system, and a granulation system. Shuliyglobal plastic granulation host has the advantages of low noise, strong stability and long life

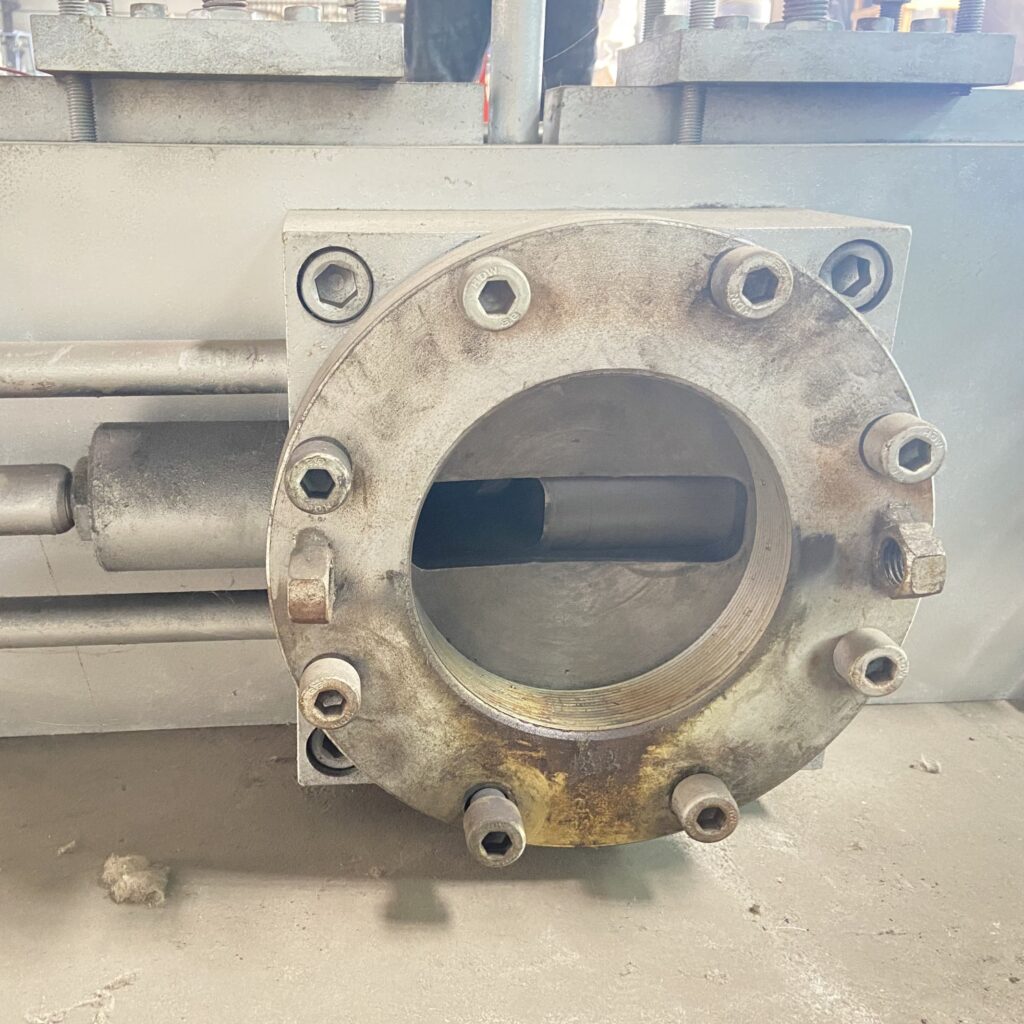

Transmission system:

The function of the transmission system is to drive the screw. The screw supplies the torque and speed required during the extrusion process and is generally composed of a motor, reducer and bearings.

Heating and cooling equipment:

The necessary conditions for the granulator to function during the plastic extrusion process are heating and cooling. The control system of the plastic granulator includes a heating system, a cooling system and a process parameter measurement system, which is mainly composed of electrical appliances, instruments, actuators, etc.

There are three heating methods: electromagnetic heating, ceramic heating, and heating ring heating.

1.Electromagnetic heating is the most effective heating method.

2.Ceramic heating is the preferred heating method for customers in countries such as Saudi Arabia.

3.The iron heating device is easy to use, safe and has a long service life.

plastic extrusion system:

The extrusion system includes screw, barrel, hopper, die and die. The plastic is plasticized into a uniform melt through the extrusion system, and a continuous extrusion die is formed under pressure during processing.

cooling pool:

The extruded plastic strips are cooled in the pool and then enter the granulation system.

Pellets cutting machine:

The plastic pelletizer evenly cuts the cooled plastic strips into fixed plastic pellets.

Contact us for plastic granulator machine price!

Are you interested in it ?If so, we are more than happy to assist you! We specialize in personalized solutions for our customers and make sure to provide you with the best quote for plastic film recycling machines according to your needs and budget. Please feel free to contact us.we also have plastic film recycline line.If u need,welcome to call me.

plastic pelletizer machine details