How to Choose Plastic Pelletizing Machine

How to Choose Plastic Pelletizing Machine

For customers who want to buy plastic granulators, how to choose a suitable plastic granulator is crucial. Customers can use granulators to recycle plastics (eps, pp, pvc, etc.) in daily life and use them for their own investment and sales, etc. Therefore, how to choose a good granulator requires attention to the following points.

1.Find out What kind of waste plastic can be processed?

As we all know, there are many kinds of plastic waste in life, such as pp, pe, pvc, etc. Different types of plastics correspond to different granulators. Therefore, when customers buy machines, they must first figure out what type of waste they are dealing with, which can help customers solve the problem efficiently. Shuli plastic granulator can recycle PP plastic, PE plastic, HDPE plastic, LDPE plastic, LLDPE, EPS foam, EPE foam and other waste plastics. You can leave your waste plastic materials here and let our professional sales manager give you advice.

2.Choose Reliable Plastic Granulator Manufacturers

Nowadays, there are many manufacturers selling plastic granulators on the market. It is recommended that customers choose experienced companies because the quality, after-sales and professional knowledge are guaranteed.

Shuliy provides One-stop service: From product consultation to delivery and installation, we provide a one-stop solution to help customers save time and effort.

Customized service: We can customize production plans and production lines according to customer needs, issue layout drawings, and ensure that customers get satisfactory solutions.

One-to-one service: We are customer-centric and responsible for the whole process. We will update the production and delivery progress for customers at any time to meet customer needs.

After-sales guarantee: We support online or offline door-to-door installation, provide after-sales document support (operation manual, maintenance manual), and provide online customer service to solve problems at any time. In addition, we also provide online training and regular telephone return visits to ensure that customers can get timely help and support.

If you want to find a reliable plastic granulator manufacturer, you’d better ask Shuliy Group.

After all, our plastic granulator factory has been in operation for 12 years and has rich experience.And provide high quality service,Welcome to consult us and visit our factory!

3.From the performance of plastic granulator:

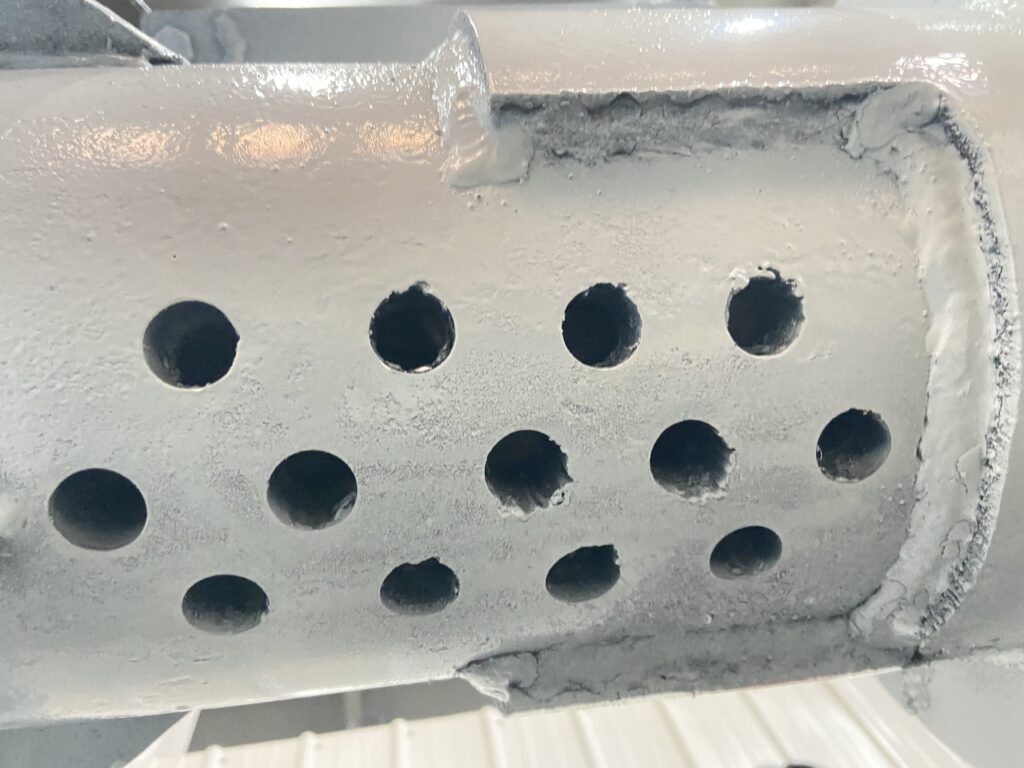

Plastic granulator can be divided into single screw granulator and twin screw granulator according to the number of screws. When the single screw granulator is working, the plastic is transported forward in the barrel in the form of a spiral line; when the twin screw plastic granulator is working, the plastic is transported forward in the barrel in the form of a straight line.

From the working principle, after the twin screw plastic granulator is stopped, the material in the machine can be basically emptied, while a small amount of residual material will remain in the single screw machine. Most plastics can be granulated, and single screw and twin screw can be used at will.

In the manufacture of recycled plastics, single screw plastic granulator has a larger screen changing die surface, which makes it easier to discharge materials and has better effects; when it comes to modified plastics, masterbatches, and mixed color extraction, the two machines have the same good effect; when it comes to the manufacture of stretched glass fiber and submarine cross-linked cable materials, only twin screw granulators can be used.

In addition, in terms of machinery procurement costs and later production costs, the single-screw granulator has a much lower chance, while the twin-screw granulator is at a clear disadvantage. Therefore, when purchasing equipment, it is necessary to choose the corresponding equipment according to the different products produced by the company.