EPS Foam Granulation Line

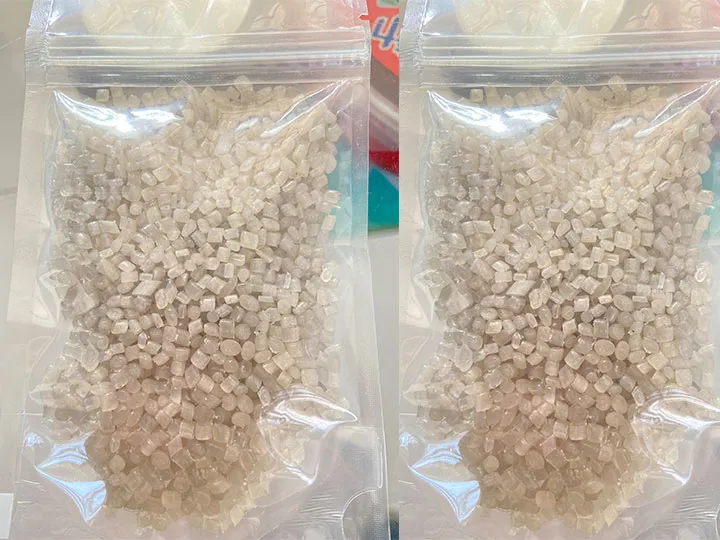

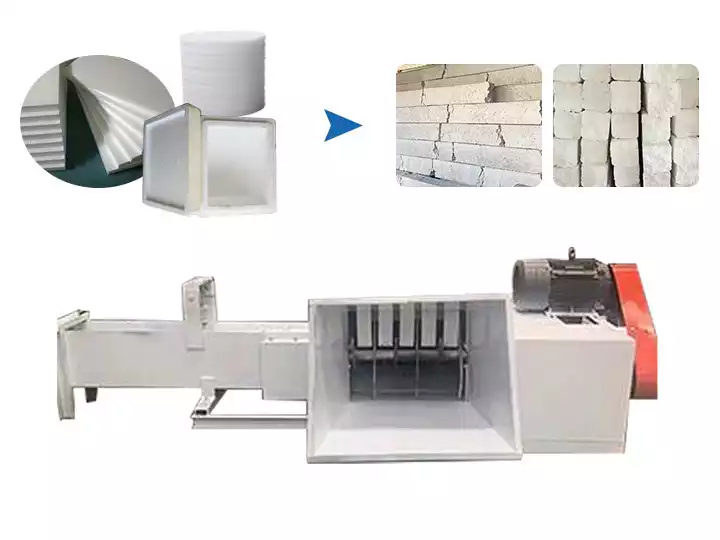

The EPS foam granulation line consists of five main single machines: plastic foam crusher, plastic foam extruder, cooling tank, EPS granule cutter and storage box. It is a plastic solution designed for EPS EPE foam recycling. The final product is plastic granules with a production capacity of 100-500 kg per hour. If you need other output, please contact us and we can also customize it for you.

What are the waste EPS and EPE materials?

EPS (expanded polystyrene) is a lightweight polymer. It uses polystyrene resin to add a foaming agent, and at the same time heats it to soften and produce gas to form a rigid closed-cell structure foam. This uniform closed cavity structure makes EPS have the characteristics of low water absorption, good thermal insulation, light weight, and high mechanical strength. EPS can be molded, that is, it can be pre-foamed into particles and then formed into various shapes in the mold. Poor toughness, easy to break, and general cushioning performance.

EPE (expandable polyethylene) is commonly known as pearl cotton. Low density, good flexibility, and high recovery rate. Excellent shockproof performance, independent bubble structure, low surface water absorption. Good impermeability. Resistant to acid, alkali, salt, oil and other organic solvents, with excellent aging resistance. It does not flow at high temperatures and does not crack at low temperatures. EPE can be made into plates, sheets or tubes by extrusion or foaming, and then punched and bonded. Good toughness, not easy to break, and good cushing.

Raw Materials and Final Product For EPS Foam Granulation Line

EPE foam

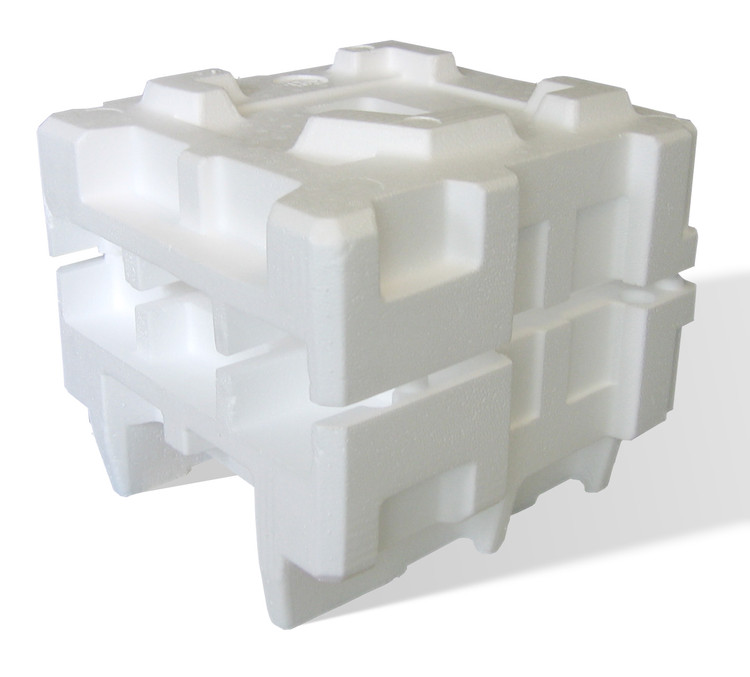

EPS foam

Final Product

Equipment introduction of plastic foam pelletizing line

This foam glue melting machine can melt waste foam into blocks, reduce the volume and facilitate transportation. It has the characteristics of large output, high efficiency, low dust, low noise, low energy consumption and easy operation. This glue melting machine controls the temperature throughout the process to avoid the phenomenon of foam burning or non-melting.

The EPS foam compactor can crush the foam first and then squeeze it out according to the spiral rotation. It can effectively double the volume of the foam, increase the density, and facilitate the transportation and recycling of the waste foam. The waste foam treated by the EPS foam compactor has the following characteristics: high density after compaction, easy to transport. Easy to cut after compaction, easy to stack and store. The machine is simple, practical and easy to operate. Economical and environmentally friendly, cold pressing treatment is smokeless and odorless.

The raw materials are heated and melted in the machine, and the molten foam is pulled out through the mold in the machine. The EPE foaming granulator consists of a power distribution cabinet, air inlet, protective cover, exhaust port, and die head. The foam granulator adopts a conical screw barrel, which has a fast feeding speed and high output.

Plastic pellet cutting machine

The plastic pellet cutter is the final process which cuts plastic long strips into pellets, and the size of the pellets can be adjusted. And the main board is set with stainless steel plate to effectively prevent plastic pellet pollution.