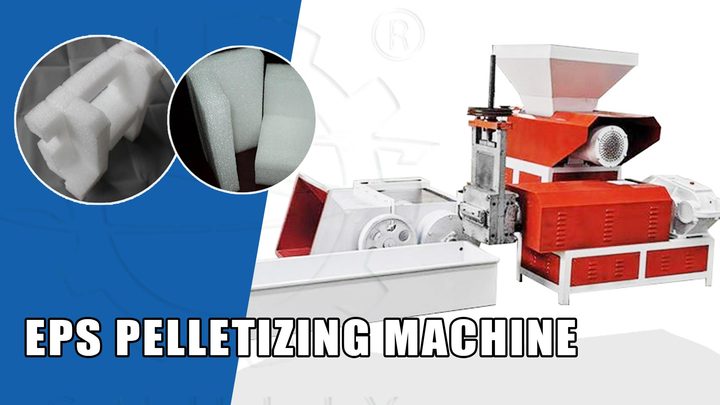

EPS Pelletizing Machine

EPS Pelletizing Machine is mainly used to re-granulate waste EPS foamed polystyrene, and is suitable for the re-granulation of foam boxes, foam boards and foam corner protectors. After a series of heating, extrusion and molding processes, the foam waste is converted into plastic pellets for reuse. And recycling EPS particles helps minimize the waste of waste foam materials.

Raw Materials of EPS pelletizer

EPS granulator is a special machine for crushing and granulating waste foam and pearl cotton. It is made of polystyrene through special processing technology. Usually used in packaging materials and various household items, such as foam fast food boxes, foam packaging boxes, refrigerator packaging foam and other white foam waste.

Video of plastic foam pelletizing process

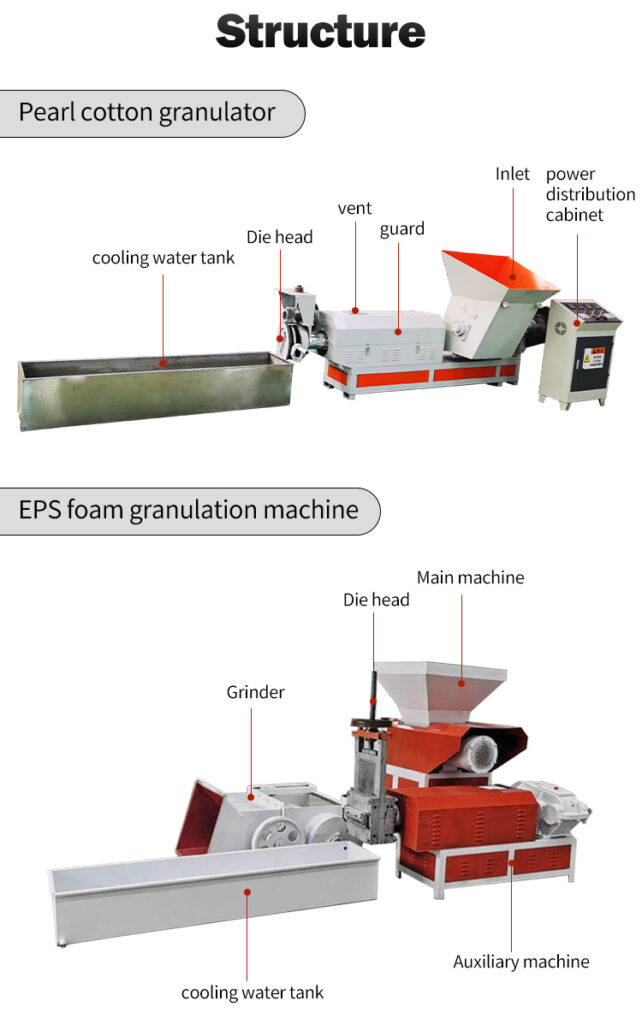

Structure of EPS pelletizer

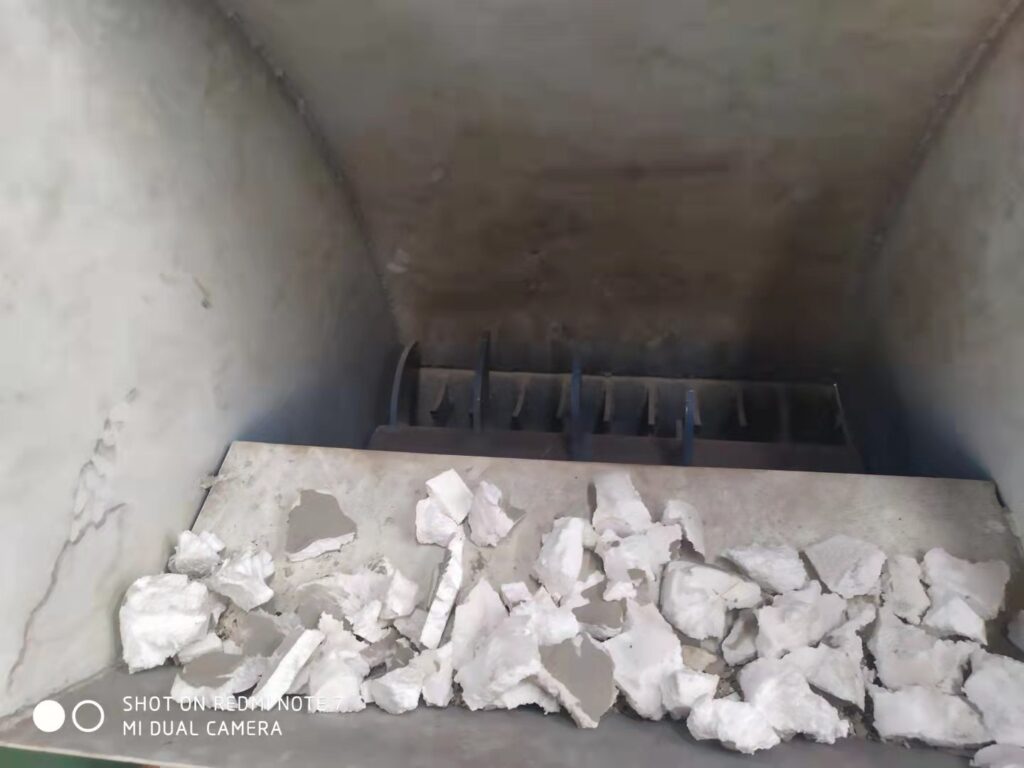

Recycling process of plastic foam extruder

- crushing—plasticizing—drawing—cooling—cutting

- The main process of EPS foam recycling line is very simple.

- Firstly, the waste plastic foam is crushed by EPS foam melting machine. Then the EPS foam is filled into the hopper and is melted and extruded to the auxiliary machine by the main machine of the EPS granulator. After secondary plasticization, the electric screen changing die filters the impurities and enters the cold pool for cooling then enters the pelletizer for cutting to get uniform EPS pellets.

Parameters of plastic foam extruder

| Type | Capacity (KG/H) | Motor (KW) |

| 220 (Double reduction gear) | 150-175 | 15 |

| 270 (Double reduction gear) | 200-225 | 18.5 |

| 220 (Single reduction gear) | 150-175 | 15 |

| 270 (Single reduction gear) | 200-225 | 18.5 |

| 320 (Double reduction gear) | 275-300 | 18.5 |

| 350 (Double reduction gear) | 325-375 | 22 |

Advantage of EPS foam pelletizing machines

- Automate production and save labor. The design of the feed opening takes into account the different densities of the materials. Customers can control the feeding speed.

- The main and auxiliary screw barrels are made of imported high-strength and high-quality carbon structural steel, which is strong and durable.

It is produced with main and auxiliary machines, and the heating temperature is stable, which effectively improves the molecular structure of the material, enhances air permeability, and significantly improves the quality of the particles. - The temperature control box allows customers to understand the screw temperature and other working conditions, and customers can adjust it according to the color of the noodles. It avoids overheating or melting failure and also facilitates the creation of more transparent particles.

- Customized design can be used independently or integrated into the entire foam recycling production line with crushers and compactors. Provide online installation guidance and other training services.

- The main and auxiliary machines are used in supporting production, and the heating temperature is stable, which effectively improves the molecular structure of the material and enhances air permeability, improving the quality of the particles!

- The EPS granulating unit is mainly composed of a crusher, a main machine, and an automatic traction and cutting machine. The main machine adopts an automatic screen changing device.

The screw and barrel of the main and auxiliary machines are made of high-strength carbon structural steel.

The foam granulator adopts a conical screw barrel, which has fast feeding speed and high output.

Some details and accessories

our service

We provide free but professional product consultation services. Typically, our sales consultants will respond within 24 hours.Welcome to inquire!

- Welcome to our factory to visit plastic granulator and other recycling equipment. If you are unable to visit the factory, our staff will send you pictures and videos, please feel free to contact us.

- After-sales engineers can assist you in installing the machine. After the machine arrives, our engineers will help you online to set up and debug the machine.

- All plastic recycling machines of Shuli Machinery enjoy one-year free warranty. Please feel free to contact us.