PET Bottle Washing And Granulating Line

PET Bottle Washing And Granulating Line

Type: hot washing, cold washing.

Capacity: 500kg/h, 1t/h, 2t/h, 3t/h, 5t/h.(customized capacity available)

Common raw materials: various PET (polyester) plastics, such as water bottles, cola bottles, PET plastic bottles, etc.

PVC content/(mg/kg)≤500.

True color content/% ≥90.00.

Moisture/% ≥3.0.

Impurity content/(mg/kg)≤800.

Bulk density: < 0.3G/CM3

Total impurities: < 320ppm

Metal content: < 20ppm

Flake size: 16mm-18mm, can be customized.

Function: crushing PET plastic bottles into pet flakes and washing.

Warranty: 1 year.

Advantage:Energy saving, modular design, simple operation.14+years of R&D experience, high cost performance, fast delivery, automation, less labor, low energy consumption, high efficiency.

Service: Free one-stop customized solutions. Installation and commissioning. Free training operation. Free design of factory installation drawings, welcome to visit our factory.

PET Bottle Washing And Recycling Machine Process Flow:

Climbing Conveyor→Label Removing Machine→Sorting Conveyor→Climbing Conveyor→PET Bottle Crusher Machine→Screw Conveyor→separating machine→Screw Conveyor→High Temperature Washing Barrel→Screw Conveyor→Rubbing Washing Machine→PET,PP,PP washing and separating machine→PET Chips Dewatering Machine→Plastic Flakes.

PET Bottle Washing Line Applicable Materials

PET bottles, PET baling bricks, waste PET Coke bottles, soda bottles, drinking water bottles, juice bottles, tea beverage bottles and other mineral water bottles.

Plastic Flakes

Shuliy PET Bottle Washing Granulating Line

PET Bottle Washing And Granulating Line are complete solutions for converting dirty PET bottles into clean PET flakes for processing into plastic pellets or the production of a variety of finished plastic products.

We offer standard washing granulating capacities from 500 kg/hour to 5 tons/hour, and can also customize higher capacity PET Recycling washing lines.

Shuliy’s PET recycling production line is fully automatic, and each recycling machine is connected by a belt or screw conveyor. In addition, the entire cleaning line can be controlled from a central electrical control panel and cabinet.

If your raw material is other plastics, it doesn’t matter, please leave a message to me, and the sales manager will give you a perfect solution based on your raw materials.

Shuliy is a trustworthy plastic recycling machinery manufacturer, welcome to visit the factory.

Our Services

Shuliy is an experienced supplier who has been rooted in the plastics industry for decades and enjoys a global reputation for providing high-quality machines and professional services. Welcome to contact us!

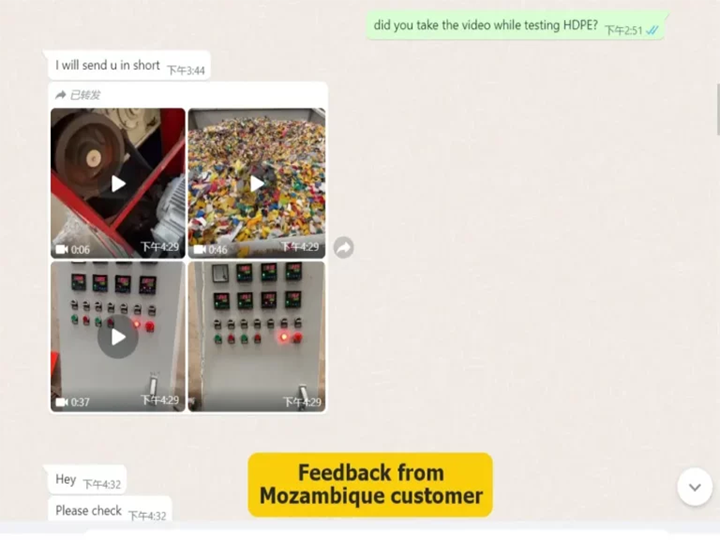

Rich experience,Global Cases

With more than 10 years of experience, Shuliy machinery shipped to Ghana, Bhutan, Peru, Nigeria, Tanzania, Türkiye and other countries, and is well-known all over the world. Welcome to consult!

Perfect after-sales

Free online installation service with machine layout manuel and connection manual,Life time consultant service.If the customer needs to provide engineers for installation

Strong factory

Shuliy has four clean, tidy and bright factories covering a large area, and the workers have rich experience and technology, welcome to visit!

Professional engineers

Engineers are experienced and skilled to ensure the quality of the machine. Sample testing will be carried out after the machine is completed.

Customized solutions

Provide customized services according to customer needs to ensure that customers buy satisfactory machines

Certificate

CE certificate, ensure the quality of the machine.

Other accessories

Plastic washing tank

Because the cap material of plastic bottles is PP, in order to collect PET flakes, the plastic washing machine will separate the cap from the bottle flakes.

Plastic friction machine

Friction cleaning is to remove the adhesion on the bottle flakes with the brushes inside the plastic friction machine. This plastic bottle recycle machine will clean the PET flakes efficiently.

Plastic bottle label remover

Most of waste plastic water bottles have PVC plastic labels, and the label removal machine can efficiently remove the plastic labels for the next step of recycling.

PET bottle crusher

The plastic crusher is the key machine to recycle plastic bottles, it will efficiently smash the plastic bottles into small pieces, and the unique design can prevent problems such as jamming and insufficient power.